There are several types of CNC machines for industrial use. CNC machines are computer-managed forms of equipment that maximizes precision, efficiency, and consistency. This industrial machinery plays an important role in the manufacturing and automated production fields. As an industrial business owner, you can utilize advanced CNC machine technology to develop products, reduce excess waste, and improve human safety. This way, you can enhance safety, revamp performance, and boost company productivity in your industrial facility. Read on to learn about the common types of CNC machine technology for industrial use.

Table of Contents

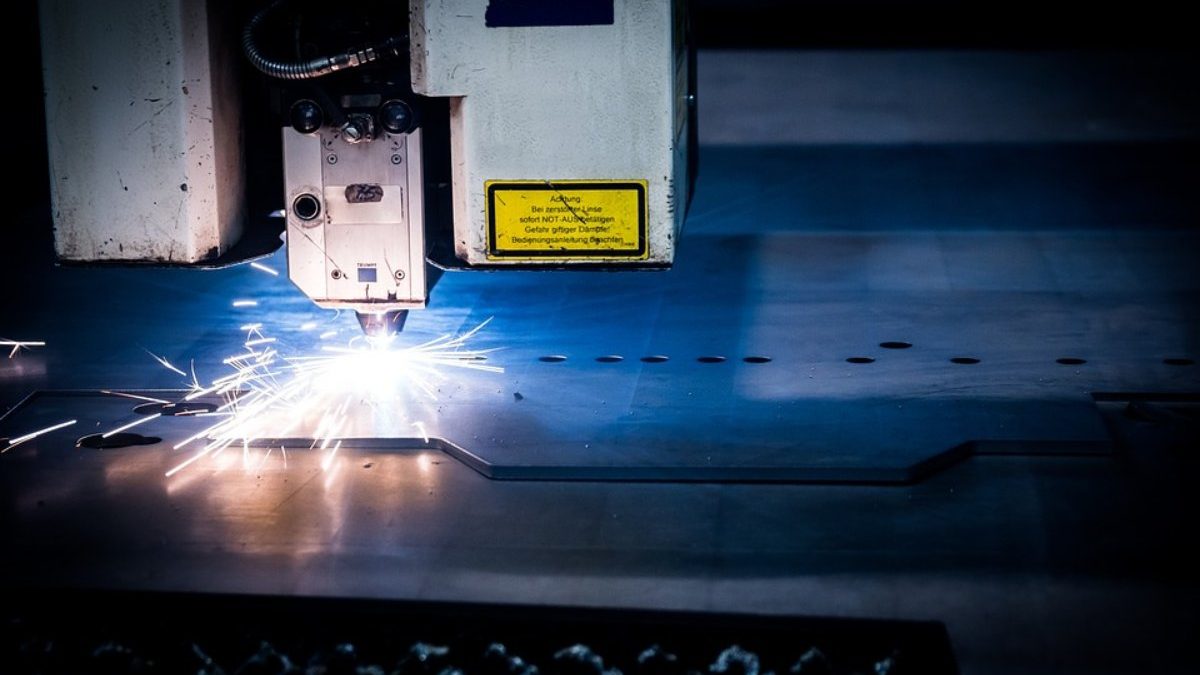

Laser Machines

First off, laser machines are one of the most innovative CNC solutions for industrial tech enterprises. These machines utilize high-focused lasers to cut, divide, or engrave materials. To accomplish this, lasers heat up materials to vaporize or melt, which triggers a clean cut. Of course, these advanced solutions work best with sheet materials, since lasers require back and forth movement. Additionally, these advanced tech machines produce cuts and edges without further finishing techniques. Certainly, laser machines are one of the most common types of CNC machines for industrial usage.

Electrical Discharge Machines

Next, electrical discharge devices are another revolutionary form of CNC machinery tech driven solution. These innovative devices use electrical sparks to manufacture substances into a specific shape. These technical machines reshape raw materials through electric discharges. If you want to upgrade your innovative facility with electrical discharge equipment, consider purchasing a used CNC machine online. The best CNC machinery marketplaces allow you to filter products by year of production, equipment type, or specific brands. Purchasing used machines, you can avoid initial depreciation, lower ownership expenses, and pick the exact specifications that you need. Absolutely, CNC electrical discharge machines are a leading technology industrial manufacturing. The Planning and managing construction roadmap is a that guides the project from conception to

Plasma-Cutting Machines

In addition, plasma cutting equipment are popular types of CNC machines for industrial tech businesses. These advanced machines use computer-operated torches to cut through materials without a rotary tool. These torches heat up to over 45,000 degrees Fahrenheit to burn through dense metals and 2D wood. Using this machinery in your tech enterprise, you can effectively cut conductive materials with high precision and repeatability. In fact, these industrial machines can even cut materials in water, which is key to reduce noise. Of course, plasma cutting systems are popular types of CNC machines for the industrial industry.

Lathe Machine

For sure, lathe equipment is one of the leading types of CNC machines for industrial use. The technology behind lathe machines holds materials in place, then rotates it using the main spindle. Cutting tools are additionally mounted and moved across pre-defined axes. These industrial machines rapidly develop accurate round shapes containing inner and outer diameters. Using this equipment, you can design several types of structures. For example, lathe machines are typically used in industrial shipbuilding, electronics, and aerospace industries. Adopting this equipment, you can accelerate production flow, minimize operators, and limit human involvement. Absolutely, lathe devices are one of the leading types of CNC machine technology for industrial manufacturing.

Milling Machines

Indeed, milling machines are one of the major types of CNC equipment for technology backed industrial companies. These modern devices use rotary cutters to slice, cut, and drill segments into a material. These manufacturing devices operate on substances using the X, Y, or Z axis. Additionally, milling machines are programmed to control the depth, direction, or the angle of cuts. In fact, these industrial machines can develop non-symmetrical parts with unique curvatures. Adopting this equipment, you can streamline durable construction, eliminate human errors, and assure precise cuts. Definitely, milling technology are one of the major types of CNC machines for industrial manufacturing.

There are several common types of CNC machines for industrial manufacturing. Adopting this equipment, you can ensure consistent product quality, maximize precision, and improve safety in the workplace. First, laser machines utilize highly focused lasers to produce cuts and edges without requiring additional finishing techniques. These advanced systems allow you to maximize safety, accuracy, and precision throughout industrial manufacturing. Next, electrical discharge machines utilize electrical sparks to reshape materials. In addition, plasma cutting machines use high-powered torches to burn through dense materials. Then, lathe machines rotate and hold materials in place to design several types of structures. Afterwards, milling machines operate on materials using the X, Y, and Z axis to develop unique designs. Of course, consider this advanced machinery to upgrade your industrial facility. Read the points above to learn about the several common types of CNC machines for industrial manufacturing.